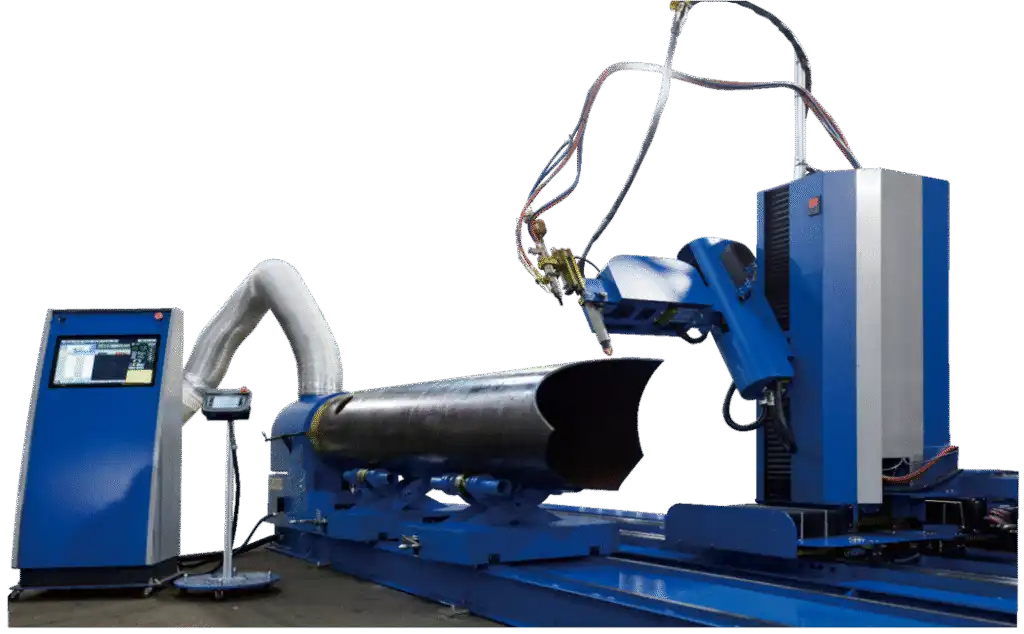

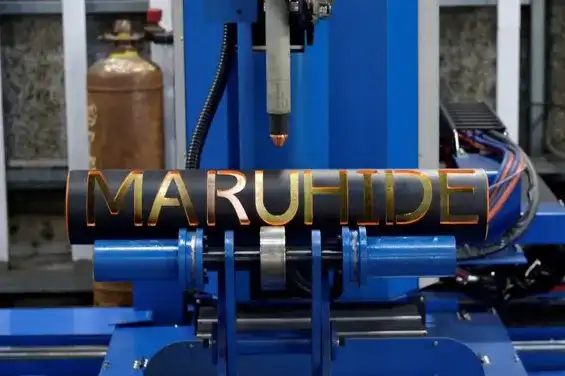

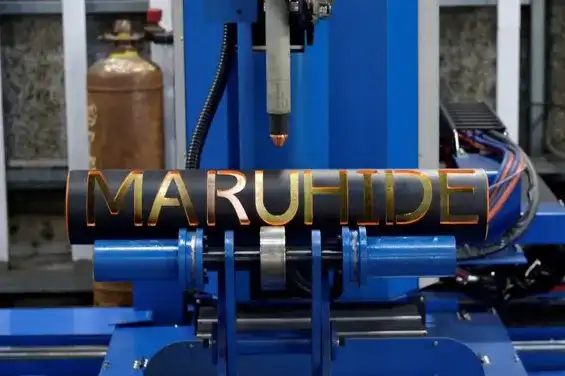

CNC automatic pipe cutting machine “PIPE COASTER” not only cut pipes correlatively

but also simplify complicated work such as marking by sharing database,

and has gotten great evaluation by users from all over the world.

Applying the experience and the technologies for a few decades into latest computer system,

PIPE COASTER is highly user-friendly to everyone.

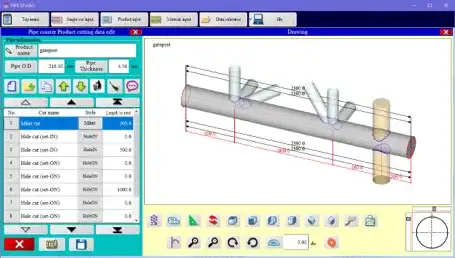

Software’s such as 3D direct linking are the futuristic systems that simplified complicated work.

HID series has various models that cover pipe diameters from 34 to 3,000 mm,

suitable for various fields of piping applications.

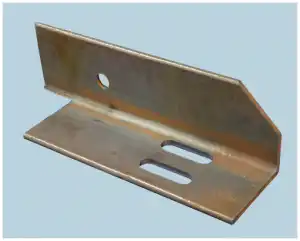

With the flexibility to process Tube, I-Beam, Tapper, Channel, L, Multi fit cuts, and more. From the oil/gas industry, light poles, structural and everything in between this machine make your job easier.

| Specifications/Model | 400MA | 650MA | 1000MA | 1350MA | 1500MA |

|---|---|---|---|---|---|

| Cutting pipe diameter (mm) | 34〜 406.4 | 60.5〜 660.4 | 76.3〜 1016 | 165.2〜 1371.6 | 267.4〜 1524 |

| Axis numbers (model) | 5axis(MA5) / 6 axis(MA6) / 7 axis(MA7) | ||||

| Interactive cutting software (PIPE STUDIO),panel,remote panel | Standard | ||||

| Torch travel length (mm) | 1000/3000/6000/9000/12000/15000/18000 | ||||

| Pipe trolley numbers | Torch rail 1000 to 3000 mm x2sets / 6000 to 9000 mm x 3sets / 12000 mm or more x5sets | ||||

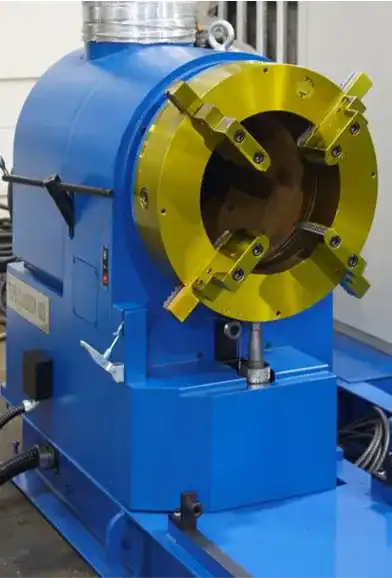

| Self-centering pipe chuck | 400MA, 650MA, 1000MA 4 or 5 jaws / 1350MA, 1500MA 3jaws | ||||

| Laser sensing system | Standard | ||||

| Plasma cutting machine | Standard | ||||

| Oxy/fuel cutting | Option | ||||

| Manual/Auto pre-heating unit | Option | ||||

| Auto pre-heating system | Option | ||||

| Auto marking system (powder) | Option | ||||

| Auto marking system (inkjet) | Option | ||||

| Auto marking system (laser) | Option | ||||

| Motorized clamping system (chuck) | Option | ||||

| Motorized traveling system (pipe trolley) | Option | ||||

| Touch sensor (side) | Option | ||||

| Cutting system for rear side of chuck | Option | ||||

| Loading-unloading system with chuck up/down function | Option | ||||

| Square rotator | Option | ||||

| Fume collector | Option | ||||

| Interactive cutting software (PIPE STUDIO) | Standard |

| PIPE STUDIO for PC | Standard |

| Nesting software | Standard |

| Data conversion software for AUTOCAD | Standard |

| Data conversion doftware for TEKLA | Option |

| Data conversion doftware for CSV | Option |

| SHS, RHS cutting software | Option |

| Structural shaped steel and flat bar cutting software | Option |

| DXF template export software | Option |

| Marking software | Option |

| Foot print for welding software | Option |

| Cutting software for taper tube | Option |

| Cutting software for AWS/API | Standard |

Looking to update your current system with a more productive New Tanaka Fiber Laser? Reach out to us at [email protected]. Check out the New advancements Tanaka Lasers machines have to offer.

No products in the cart.

No products in the cart.